Acero para herramientas de trabajo en caliente H13

El acero H13 se utiliza para fabricar matrices de forja, matrices de extrusión en caliente y matrices de forja de precisión con gran carga de impacto; Matrices de fundición a presión para aluminio, cobre y sus aleaciones.

- fucheng steel

- Porcelana

- 1 mes

- 2000 toneladas/mes

- información

- vídeo

H13 STEEL

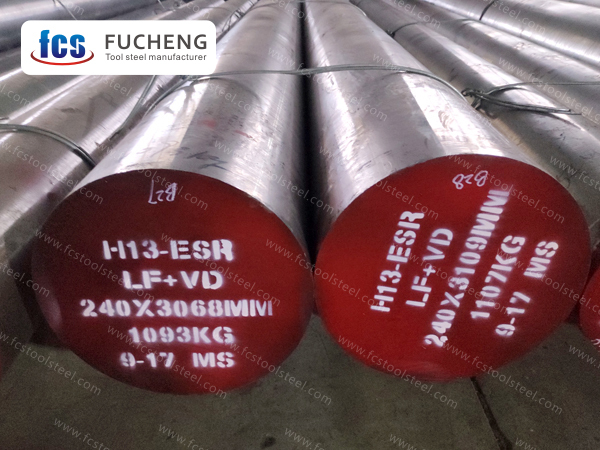

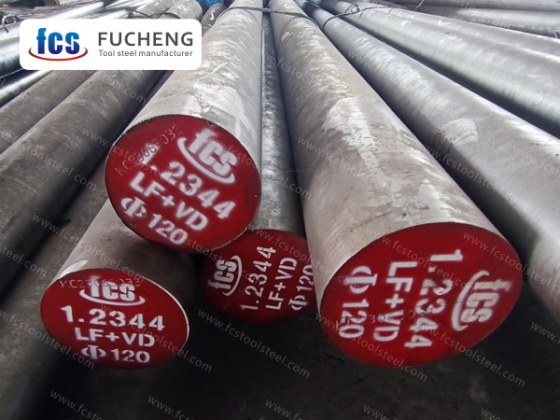

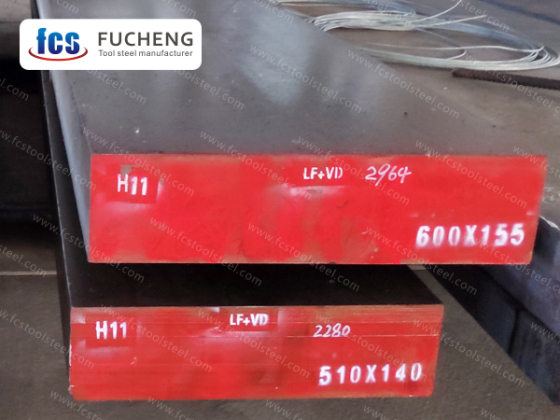

| Smelting and Manufacture Method: | LF+VD+ESR+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤229 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

H13 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| ASTM | H13 | 0.32~0.45 | 0.80~1.20 | 0.20~0.50 | 4.75~5.50 | 1.10~1.75 | 0.80~1.20 |

| DIN/W-Nr. | X40CrMoV5-1/1.2344 | 0.37~0.42 | 0.90~1.20 | 0.30~0.50 | 4.80~5.50 | 1.20~1.50 | 0.90~1.10 |

| JIS | SKD61 | 0.35~0.42 | 0.80~1.20 | 0.25~0.50 | 4.80~5.50 | 1.00~1.50 | 0.80~1.15 |

APPLICATION

H13 die steel is used to manufacture forging dies, hot extrusion dies and precision forging dies with large impact load; Die casting dies for aluminum, copper and their alloys.

H13 Steel Characteristics

H13 mold steel is a widely used and representative hot work mold steel, which is valued for its excellent performance and multiple uses. This steel contains a high content of carbon and vanadium, with high hardenability and resistance to hot cracking, good wear resistance, and relatively weakened toughness. At higher operating temperatures, it can still maintain good strength and hardness.

H13 mold steel has excellent comprehensive mechanical properties and high tempering stability. In addition, it also has good heat resistance, allowing it to maintain excellent performance in high-temperature environments. Due to its low carbon content, its secondary hardening ability during the tempering process is slightly lacking. However, by using carburizing or nitriding processes, its surface hardness can be effectively improved.

It is worth noting that although H13 mold steel undergoes heat treatment during the manufacturing process, this does not result in excessively high deformation rates. In fact, the deformation after heat treatment is quite small. In addition, H13 mold steel also has good machinability and moderate decarburization resistance.